ABSORPTION

Falling Liquid solvent absorbs the gas in the absorption column & is then sent into any one of he following unit:- Distillation, stripping section, removal through precipitation & settling, neutralization, oxidation, reduction & hydrolysis.

Purpose: - Gas purification

- Gas separation

- Product recovery

- Solvent recovery

Solvent Properties:

- Solubility of gas should be high in selected solvent. ( If not, then absorption is a waste!! )

- Low volatility organic liquid ( but water is preferred in many cases, due to easy availability & removal of water soluble gases like, HF, HCl, SiF4 ).

- Low vapor pressure ( to reduce evaporative loss of solvent )

- non-toxic, non-flammable, non- corrosive

- Low viscosity

Internals of Packed tower

- Packing support plate: It must bear the weight of the packings & allow unrestricted flow of down coming liquid. Drawback is that, that the packing blocks some holes, thus reducing the tower capacity.

- Liquid distributor: Placed 6-12 inch above packing for allowing gas disengagement from the bed. Absorption & stripper columns require only one distributor, whereas, Distillation column requires 2 (feed & reflux)

- Liquid re-distributor: Some part of entering liquid flows through the wall without coming in contact with the gas flowing counter currently, thus we need a liquid re-distributor to collect the down coming liquid and distribute it uniformly throughout the bed and thus increase the efficiency of the tower.

- Demisters / Entrainment separators: Generally installed in exit gas streams for arresting the liquid droplets entrained in the gases. If demisters are not installed they can corrode / choke downstream equipments like heat exchangers tubes, damage tube sheets, contaminate products etc.

- Against all acid gases, metal tower, metal plates, metal packing or any other metal internals can have deleterious effect.

- Same is the case with organic liquid and plastic packing.

- Ensure internal cooling facility is available when materials and gases releases high heat of absorption.

Dry & wet random packing:

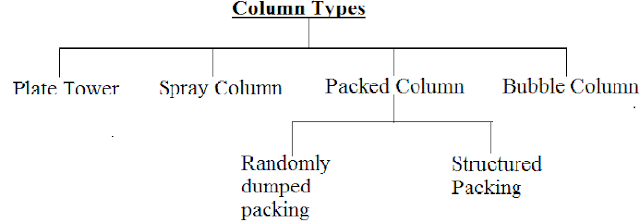

Packed & plate column: